module 52 The Three Rs and Composting

Almost every schoolchild in the United States has heard the phrase “reduce, reuse, and recycle.” In recent years, composting has been added to the list of actions one should take before adding material to the waste stream. In this module we will examine the three Rs and composting.

Learning Objectives

After reading this module, you should be able to

describe the three Rs.

understand the process and benefits of composting.

The three Rs divert materials from the waste stream

Reduce, reuse, recycle A popular phrase promoting the idea of diverting materials from the waste stream. Also known as the three Rs.

Starting in the 1990s, people in the United States began to promote the idea of diverting materials from the waste stream with a popular phrase “Reduce, Reuse, Recycle,” also known as the three Rs. The phrase incorporates a practical approach to the subject of solid waste management, with the techniques presented from the most environmentally beneficial to the least (FIGURE 52.1).

Reduce

Source reduction An approach to waste management that seeks to cut waste by reducing the use of potential waste materials in the early stages of design and manufacture.

“Reduce” is the first choice among the three Rs because reducing inputs is the optimal way to achieve a reduction in solid waste generation. This strategy is also known as waste minimization and waste prevention. If the input of materials to a system is reduced, the outputs will also be reduced; in terms of waste, this means that when less material is used, there will be less material to discard. One approach, known as source reduction, seeks to cut waste by reducing the use of potential waste materials in the early stages of design and manufacture. In many cases, source reduction also increases energy efficiency because it means that manufacturing produces less waste to begin with and can minimize disposal processes. Since fewer resources are being expended, source reduction also provides economic benefits.

Source reduction can be implemented both on individual and on corporate or institutional levels. For example, if an instructor has two pages of handout material for a class, she could reduce her paper use by 50 percent if she provides her students with double-

Source reduction in manufacturing can happen in several ways. If the company creates new packaging that provides the same amount of protection to the product with less material, successful source reduction has occurred. Consider the incremental source reduction that occurred with purchasing music. Music compact discs were packaged in large plastic sleeves that were three times the size of the CD. Today, most CDs are wrapped with a small amount of plastic material that just covers the CD case. Many people no longer purchase CDs at all and instead download their music from the Web. Less wrapping on CDs is an example of source reduction on the corporate level. Not purchasing CDs at all is an example of source reduction on the individual level.

Source reduction can also be achieved by material substitution. In an office where workers drink water and coffee from paper cups, providing every worker with a reusable mug will reduce MSW. In some categorization schemes, this could be considered reuse rather than source reduction. Nevertheless, cleaning the mugs will require water, energy to heat the water, soap, and processing of wastewater. The break-

All of these examples achieve a reduction in material use and, ultimately, material waste, without an additional expenditure of materials or energy. For that reason, reduction is the first “R”—and it is the most environmentally beneficial.

Reuse

Reuse Using a product or material that was intended to be discarded.

Reuse of a product or material that would otherwise be discarded, rather than disposal, allows a material to cycle within a system longer before it becomes an output. In other words, its mean residence time in the system is greater. Optimally, no additional energy or resources are needed for the object to be reused. For example, a mailing envelope can be reused by covering the first address with a label and writing the new address over it. Here we are increasing the residence time of the envelope in the system and reducing the waste disposal rate. Or we could reuse a disposable polystyrene cup more than once, though reuse might involve cleaning the cup, which would add some energy cost and generate some wastewater. Sometimes reuse may involve repairing an existing object, which costs time, labor, energy, and materials.

Energy may also be required to prepare or transport an object for reuse by someone other than the original user. For example, certain companies reuse beverage containers by shipping them to the bottling factory where they are washed, sterilized, and refilled. Although energy is involved in the transport and preparation of the containers, it is still less than the energy that would be required for recycling or disposal.

We have noted that reuse is still common in many countries and that it was common practice in the United States before we became a “throw-

Recycle

Recycling The process by which materials destined to become municipal solid waste (MSW) are collected and converted into raw material that is then used to produce new objects.

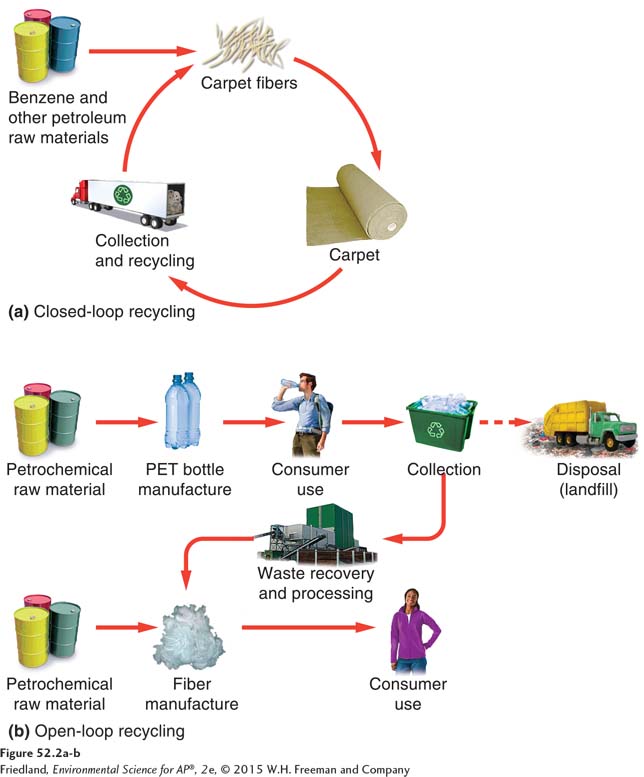

Closed-

Open-

The third “R” is recycling, the process by which materials destined to become MSW are collected and converted into raw materials that are then used to produce new objects. We divide recycling into two categories: closed-

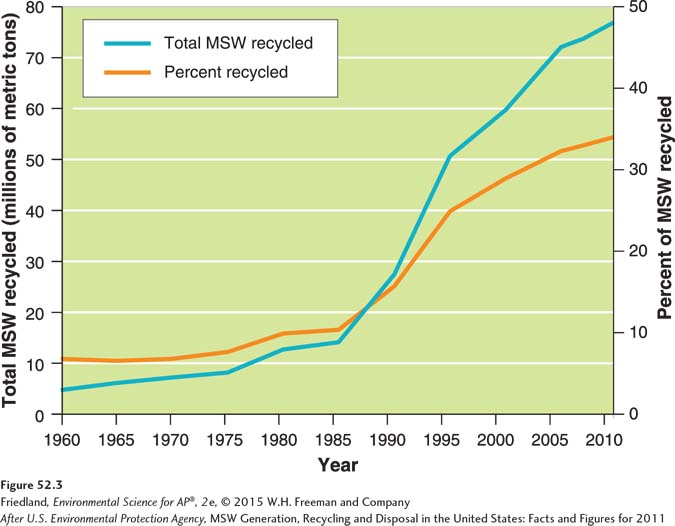

Recycling is not new in the United States, but over the past 25 years it has been embraced enthusiastically by both individuals and municipalities in the belief that it measurably improves environmental quality. The graph in FIGURE 52.3 shows both the increase in the weight of MSW in the United States from 1960 to 2011 and the increase in the percent of waste that was recycled over the same period of time. Recycling rates have increased in the United States since 1975, and today we recycle roughly one-

Extracting resources from Earth requires energy, time, and usually a considerable financial investment. As we have seen, these processes generate pollution. Therefore, on many levels, it makes sense for manufacturers to utilize resources that have already been extracted. Today, many communities are adopting zero-

Nevertheless, because recycling requires time, processing, cleaning, transporting, and possible modification before the waste is usable as raw material, it does require more energy than reducing or reusing materials. Such costs caused New York City to make a controversial decision in 2002 to suspend glass and plastic recycling. This was a major shift in policy for the city, which had been encouraging as much recycling as possible, including collection of mixed recyclables—

The New York City case is just one example of why recycling is the last choice among the three Rs. This doesn’t mean that we should abandon recycling programs. Not only does it work well for materials such as paper and aluminum, but it also encourages people to be more aware of the consequences of their consumption patterns. Nevertheless, in terms of the environment, source reduction and reuse are preferable. The environmental implications of recycling are considered further in “Science Applied 7: Is Recycling Always Good for the Environment?” that follows Chapter 17 on page 625

Composting is becoming more popular

While diversion from the landfill is usually referred to as the three Rs, there is one more diversion pathway that is equally important, if not more so. Organic materials such as food and yard waste that end up in landfills cause two problems. Like any material, they take up space, but unlike glass and plastic that are chemically inert, organic materials are also unstable. As we will see later in this chapter, the absence of oxygen in landfills causes organic material to decompose anaerobically, which produces methane gas, a much more potent greenhouse gas than carbon dioxide.

Composting Creation of organic matter (humus) by decomposition under controlled conditions to produce an organic-

An alternate way to treat organic waste is through composting. Composting creates organic matter (humus) that has decomposed under controlled conditions to produce an organic-

Outdoor compost systems can be as simple as a pile of food and yard waste in the corner of a yard, or as sophisticated as compost boxes and drums that can be rotated to ensure mixing and aeration. From the decomposition process described in Chapter 3, we are already familiar with the process that takes place during composting. In order to encourage rapid decomposition, it is important to have the ratio of carbon to nitrogen (C:N) that will best support microbial activity—

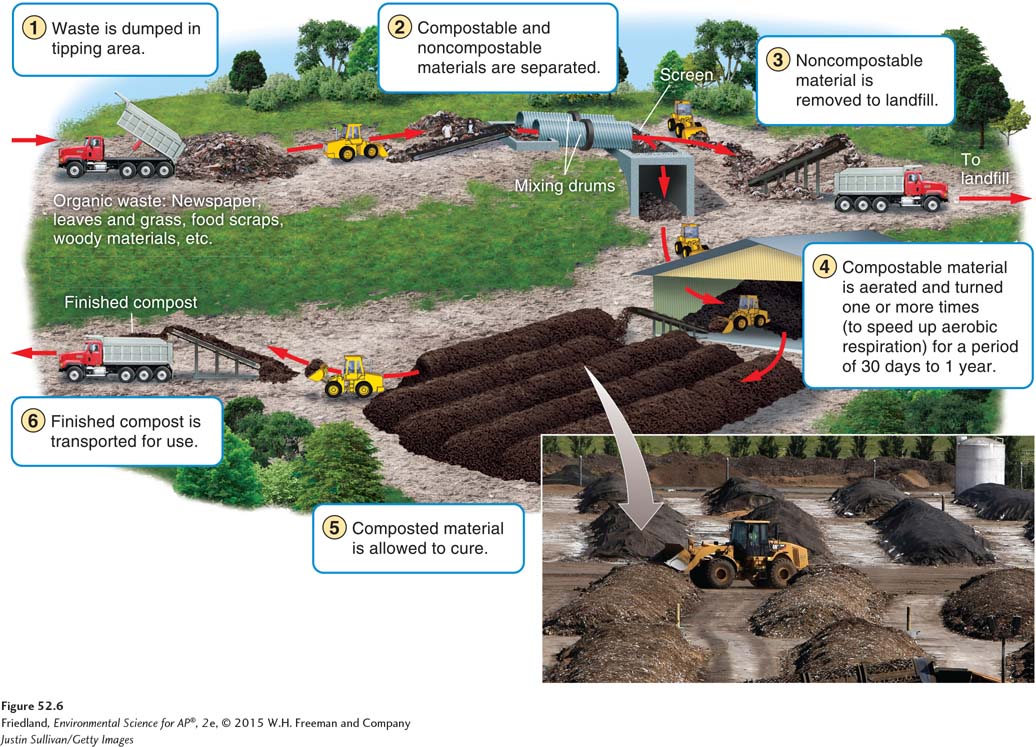

Large-

It is not necessary to have an outdoor space to compost household waste; composting is possible even in a city apartment or a dorm room. It is even possible to set up a composting system in a kitchen or basement. The very popular book Worms Eat My Garbage: How to Set Up and Maintain a Worm Composting System by Mary Appelhof has encouraged thousands of individuals across the country to compost kitchen waste using red wiggler worms. A small household recycling bin is large enough to serve as a worm box. As with an outdoor compost pile, a properly maintained worm box does not give off bad odors.

The composting process does take time and space. Source separation can be an inconvenience or, in some situations, not possible. Also, in certain environments, storing materials before they are added to the compost pile can attract flies or vermin. Finally, the compost pile itself can attract unwanted animals such as rats, skunks, raccoons, and even bears. But because compost is high in organic matter, which has a high cation exchange capacity and contains nutrients, it enhances soil quality when added to agricultural fields, gardens, and lawns.