The Industrialization of Labor

The industrialization of the United States transformed the workplace, bringing together large numbers of laborers under difficult conditions. In 1870 few factories employed 500 or more workers. Thirty years later, more than 1,500 companies had workforces of this size. Just after the Civil War, manufacturing employed 5.3 million workers; thirty years later, the figure soared to more than 15.1 million. Most of these new industrial workers came from two main sources. First, farmers like the Leases who could not make a decent living from the soil moved to nearby cities in search of factory jobs. Although mostly white, this group also included blacks who sought to escape the oppressive conditions of sharecropping. Between 1870 and 1890, some 80,000 African Americans journeyed from the rural South to cities in the South and the North to search for employment. Second, the economic opportunities in America drew millions of immigrants from Europe over the course of the nineteenth century. Immigrant workers initially came from northern Europe. However, by the end of the nineteenth century, the number of immigrants from southern and eastern European countries had surpassed those coming from northern Europe.

Inside factories, unskilled workers, those with no particular skill or expertise, encountered a system undergoing critical changes, as small-scale manufacturing gave way to larger and more mechanized operations. Immigrants, who made up the bulk of unskilled laborers, had to adjust both to a new country and to unfamiliar, unpleasant, and often dangerous industrial work. A traveler from Hungary who visited a steel mill in Pittsburgh that employed many Hungarian immigrants compared the factories to prisons where “the heat is most insupportable, the flames most choking.” Nor were any government benefits—such as workers’ compensation or unemployment insurance—available to industrial laborers who were hurt in accidents or laid off from their jobs.

Explore

See Document 17.1 for one worker’s opinion on mechanization.

Skilled workers, who had particular training or abilities and were more difficult to replace, were not immune to the changes brought about by industrialization and the rise of large-scale businesses. In the early days of manufacturing, skilled laborers operated as independent craftsmen. They provided their own tools, worked at their own pace, and controlled their production output. This approach to work enhanced their sense of personal dignity, reflected their notion of themselves as free citizens, and distinguished them from the mass of unskilled laborers. Mechanization, however, undercut their autonomy by dictating both the nature and the speed of production through practices of scientific management. Instead of producing goods, skilled workers increasingly applied their craft to servicing machinery and keeping it running smoothly. While owners reaped the benefits of the mechanization and regimentation of the industrial workplace, many skilled workers saw such “improvements” as a threat to their freedom.

Still, most workers did not oppose the technology that increased their productivity and resulted in higher wages. Compared to their mid-nineteenth-century counterparts, industrial laborers now made up a larger share of the general population, earned more money, and worked fewer hours. During the 1870s and 1880s, the average industrial worker’s real wages (actual buying power) increased by 20 percent. At the same time, the average workday declined from ten and a half hours to ten hours. From 1870 to 1890, the general price index dropped 30 percent, allowing consumers to benefit from lower prices.

Yet workers were far from content, and the lives of industrial workers remained extremely difficult. Although workers as a group saw improvements in wages and hours, they did not earn enough income to support their families adequately. Also, there were widespread disparities based on job status, race, ethnicity, sex, and region. Skilled workers earned more than unskilled workers. Whites were paid more than African Americans, who were mainly shut out of better jobs. Immigrants from northern Europe, who had settled in the United States before southern Europeans, tended to hold higher-paying skilled positions. Southern factory workers, whether in textiles, steel, or armaments, earned less than their northern counterparts. And women, an increasingly important component of the industrial workforce, earned, on average, only 25 percent of what men did.

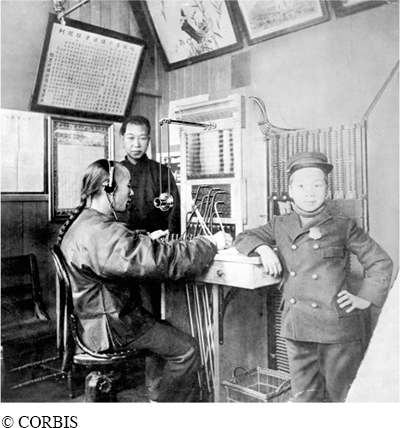

Between 1870 and 1900, the number of female wageworkers grew by 66 percent, accounting for about one-quarter of all nonfarm laborers. The majority of employed women, including those working in factories, were single and between the ages of sixteen and twenty-four. Overall, only 5 percent of married women worked outside the home, although 30 percent of African American wives were employed. Women workers were concentrated in several areas. White and black women continued to serve as maids and domestics. Others took over jobs that were once occupied by men. They became teachers, nurses, clerical workers, telephone operators, and department store salesclerks. Other women toiled in manufacturing jobs requiring fine eye-hand coordination, such as cigar rolling and work in the needle trades and textile industry.

Women also turned their homes into workplaces. In crowded apartments, they sewed furs onto garments, made straw hats, prepared artificial flowers, and fashioned jewelry. Earnings from piecework (work that pays at a set rate per unit) were even lower than factory wages, but they allowed married women with young children to contribute to the family income. When sufficient space was available, families rented rooms to boarders, and women provided meals and housekeeping for the lodgers. Some female workers found other ways to balance work with the needs and constraints of family life. To gain greater autonomy in their work, black laundresses began cleaning clothes in their own homes, rather than their white employers’ homes, so that they could control their own work hours. In 1881 black washerwomen in Atlanta conducted a two-week strike to secure higher fees from white customers.

Manufacturing also employed many child workers. By 1900 about 10 percent of girls and 20 percent of boys between the ages of ten and fifteen worked, and at least 1.7 million children under the age of sixteen held jobs. Employers often exposed children to dangerous and unsanitary conditions. Most child workers toiled long, hard hours breathing in dust and fumes as they labored in textile mills, tobacco plants, print shops, and coal mines. In Indiana, young boys worked the night shift in dark, windowless glass factories. Children under the age of ten, known as “breaker boys,” climbed onto filthy coal heaps and picked out unprocessed material. Working up to twelve-hour days, these children received less than a dollar a day.

Women and children worked because the average male head of household could not support his family on his own pay, despite the increase in real wages. As Carroll D. Wright, director of the Massachusetts Bureau of the Statistics of Labor, reported in 1882, “A family of workers can always live well, but the man with a family of small children to support, unless his wife works also, has a small chance of living properly.” For example, in 1883 in Joliet, Illinois, a railroad brakeman tried to support his wife and eight children on $360 a year. A state investigator described the way they lived: “Clothes ragged, children half dressed and dirty. They all sleep in one room regardless of sex. The house is devoid of furniture, and the entire concern is as wretched as could be imagined.” Not all laborers lived in such squalor, but many wageworkers barely lived at subsistence level.

Although the average number of working hours dropped during this era, many laborers put in more than 10 hours a day on the job. In the steel industry, blast-furnace operators toiled 12 hours a day, 7 days a week. They received a day off every 2 weeks, but only if they worked a 24-hour shift. Given the long hours and backbreaking work, it is not surprising that accidents were a regular feature of industrial life. Each year tens of thousands were injured on the job, and thousands died as a result of mine cave-ins, train wrecks, explosions in industrial plants, and fires at textile mills and garment factories. Railroad employment was especially unsafe—accidents ended the careers of one in six workers.

Agricultural refugees who flocked to cotton mills in the South also faced dangerous working conditions. Working twelve-hour days breathing the lint-filled air from the processed cotton posed health hazards. Textile workers also had to place their hands into heavy machinery to disentangle threads, making them extremely vulnerable to serious injury. Wages scarcely covered necessities, and on many occasions families did not know where their next meal was coming from. North Carolina textile worker J. W. Mehaffry complained that the mill owners “were slave drivers” who “work their employees, women, and children from 6 a.m. to 7 p.m. with a half hour for lunch.” Mill workers’ meals usually consisted of potatoes, cornbread, and dried beans cooked in fat. This diet, without dairy products and fresh meat, led to outbreaks of pellagra, a debilitating disease caused by niacin (vitamin B3) deficiency.

Although wages and working hours improved slightly for some workers, employers kept the largest share of the increased profits that resulted from industrialization. In 1877 John D. Rockefeller collected dividends at the rate of at least $720 an hour, roughly double what his average employee earned in a year. Despite some success stories, prospects for upward mobility for most American workers remained limited. A manual worker might rise into the ranks of the semiskilled but would not make it into the middle class. And to achieve even this small upward mobility required putting the entire family to work and engaging in rigorous economizing, what one historian called “ruthless underconsumption.” Despite their best efforts, most Americans remained part of the working class.

Exploring American HistoriesPrinted Page 552

Exploring American Histories Value EditionPrinted Page 409

Chapter Timeline