Chapter 2. Carbon Metabolism: Fermentation

General Purpose

This pre-lab will focus on measuring the rate of fermentation by yeast, Saccharomyces cerevisiae in two different ways: 1) directly by measuring the CO2 production using the Qubit CO2 analyzer and 2) indirectly by measuring the amount of carbon dioxide produced in alcohol fermentation using fermentation tubes.

Learning Objectives

General Purpose

Conceptual

- Describe the process of alcoholic fermentation, naming the substrate and products.

- Explain how fermentation in yeasts can be measured.

- List factors that can affect the rate of yeast fermentation.

Procedural

- Measure the carbon dioxide production in fermenting yeast cultures of various sugar and sugar-substitute solutions.

- Analyze and interpret your data.

- Understand the setup and use of the Qubit CO2 analyzer.

Background Information

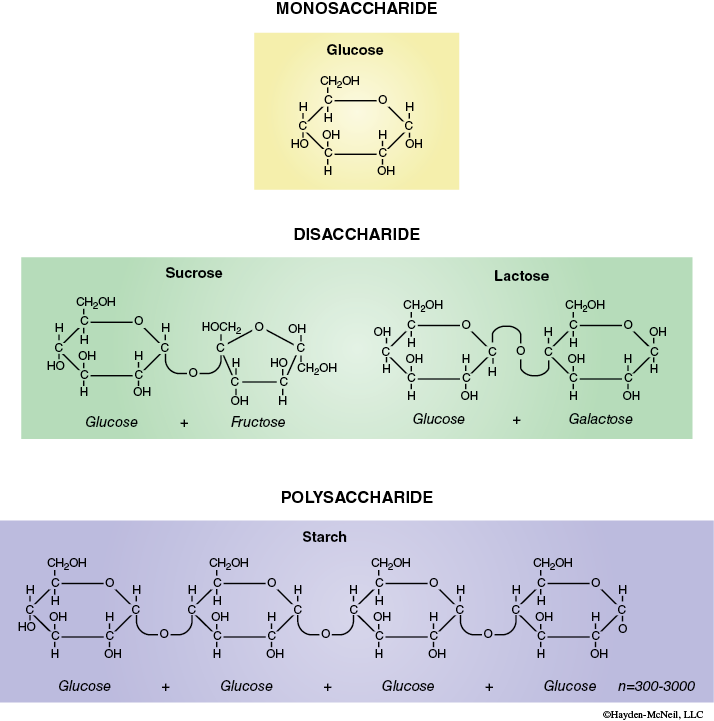

Yeast, Saccharomyces cerevisiae, strains are versatile laboratory organisms. They grow rapidly and have simple nutritional requirements. Aerobically they convert glucose to CO2 and H2O. Anaerobically they use alcohol fermentation and produce CO2 and ethanol from glucose. Glucose isn’t the only carbon source that can feed into glycolysis. Other carbohydrates (and even some amino acids) can enter the pathway at various points. The first exercise in this laboratory involves measuring the rate of alcoholic fermentation in yeast using different carbohydrate substrates. Figure 9-4 shows the chemical structures associated with the various substances you will use to measure the fermentation rate by the amount of carbon dioxide produced.

Based on what you know about the chemical structures of the substrates and the chemical pathways of fermentation, make predictions about the fermentation activity these substances will produce. Make a copy of Table 9-1 in your laboratory notebook and indicate your predictions as follows: − = no activity, + = little activity, ++ = moderate activity, +++ = high activity.

Table 9-1. Predict the fermentation activity for the carbohydrate solutions.

Direct Measurement of CO2 Production Using the Qubit CO2 Analyzer

Changes in the levels of CO2 for the experiments will be measured using the Qubit CO2 Analysis laboratory package. This instrument measures CO2 levels using an infrared gas analyzer (IRGA). The initial CO2 concentration in the gas provided to the specimen chamber can be measured. The gas can then be pumped through the specimen chamber at a known flow rate and the concentration of CO2 in the effluent gas from the chamber can be measured using the IRGA. The difference between effluent concentration and the input gas can be used to measure the fermentation rate.

To prepare for the first exercise of the laboratory, make a copy of Table 9-2 in your laboratory notebook.

Table 9-2. CO2 production.

In your laboratory notebook, write a null hypothesis and an alternative hypothesis for Exercise 1.

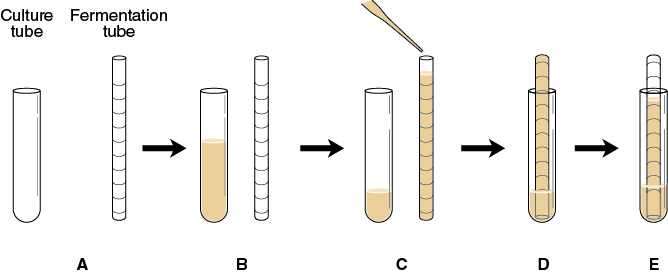

Indirect Measurement of CO2 Production Using Fermentation Tubes

Fermentation rates may also be determined indirectly by the volume of carbon dioxide released. Figure 9-5 shows the setup to collect the carbon dioxide.

Fermentation will take place in the sealed glass pipettes (fermentation tubes), each of which contains a “fermentation culture.” As carbon dioxide is produced, it displaces the fermentation culture; the displacement (in mL) is recorded as a measure of the amount of carbon dioxide produced.

To prepare for the second exercise of the laboratory, make a copy of Table 9-3 in your laboratory notebook.

Table 9-3. CO2 production in yeast.

In your laboratory notebook, write a null hypothesis and an alternative hypothesis for Exercise 2.

Pre-Lab Quiz

Proceed to the Pre-Lab Quiz