10.11 Less damaging, more efficient biofuels are under development as alternatives to oil-based fuels

As we have seen, some forms of biomass fuel development (e.g., corn-

Reducing Deforestation Due to Biofuels Production

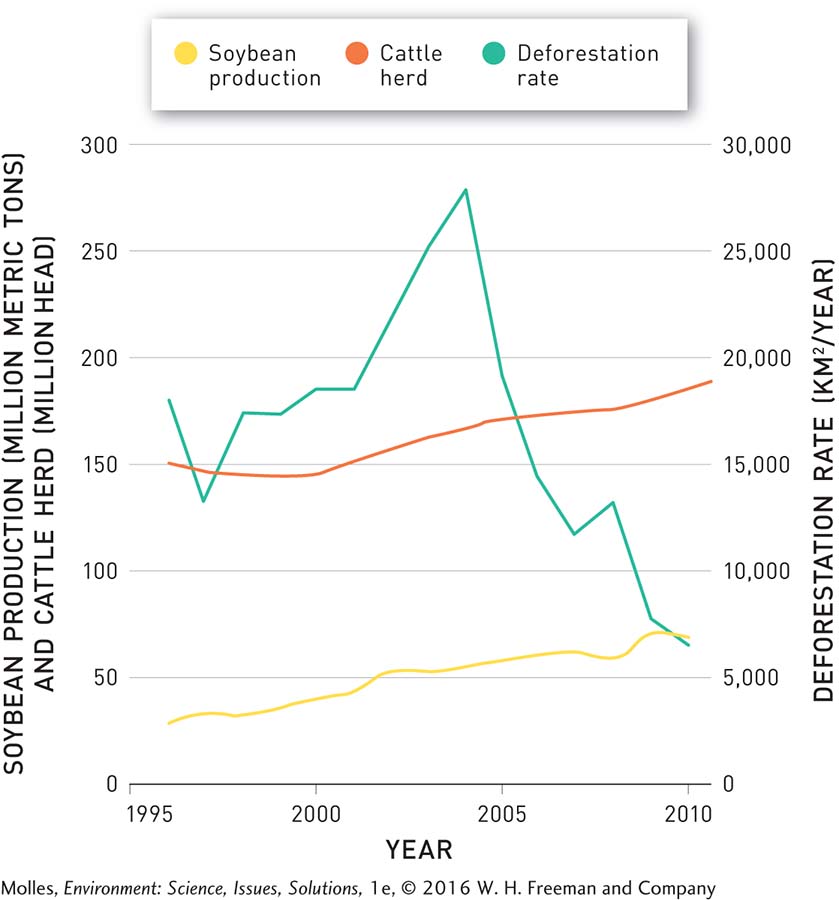

With rising demand for biofuels comes the threat of replacing natural ecosystems with bleak monocultures of oil palms or soybeans. However, Brazil, the second largest producer of biodiesel after Germany, has reduced its rate of deforestation mainly through the creation of indigenous reserves and other protected areas, including some set aside for sustainable use (Figure 10.49). The new reserves include over half the Brazilian Amazon Basin, and indigenous people now control approximately 20% of the basin. Strong enforcement and prosecution of violators, including corrupt government officials, followed the legislation creating these forest reserves.

Moreover, Brazil achieved this land protection while increasing its overall agricultural production, including production of biofuels, especially sugarcane and soybeans. In response to pressure from environmental groups, palm oil buyers and their producers in Southeast Asia have formed a coalition called the Roundtable on Sustainable Palm Oil, which seeks to reduce deforestation and environmental harm from palm oil production. In 2013 Wilmar, the world’s biggest palm oil trader, which controls 45% of the market, announced a landmark zero deforestation policy; it will avoid development on areas with high conservation value. Other companies have followed Wilmar’s lead, but it remains to be seen whether they will live up to such voluntary commitments.

Algae Can Turn Waste into Fuel

bioreactor A system designed to cultivate algae; helps filter wastewater before it enters the environment.

Another way to avoid many of the environmental threats stemming from biofuel production is to turn from terrestrial plants to aquatic algae (Figure 10.50). Growing algae, as we noted earlier, will not compete with farm production because they can be grown using brackish water too salty for irrigating crops or for drinking. They also happen to be fabulous environmental remediators. Conveniently, algae need a steady supply of carbon dioxide, along with nutrients such as nitrogen and phosphate. It turns out that agricultural and municipal wastes are rich in nitrogen and phosphorus, which can pollute the water supply by causing harmful algal blooms. Diverting these nutrients to an algae bioreactor, which is a chamber designed to cultivate algae, provides a means to recycle these nutrients and filter the wastewater before it enters the environment. In addition, by diverting the carbon dioxide generated by electrical generating stations into algal cultures, it will be possible to enhance their growth and sequester carbon emissions at the same time.

How might a whole ecosystem approach to biofuel production reduce costs and improve production?

Cellulosic Ethanol

Corn-

In 2013 the cost of cellulosic ethanol was still 30% higher than a liter of corn-

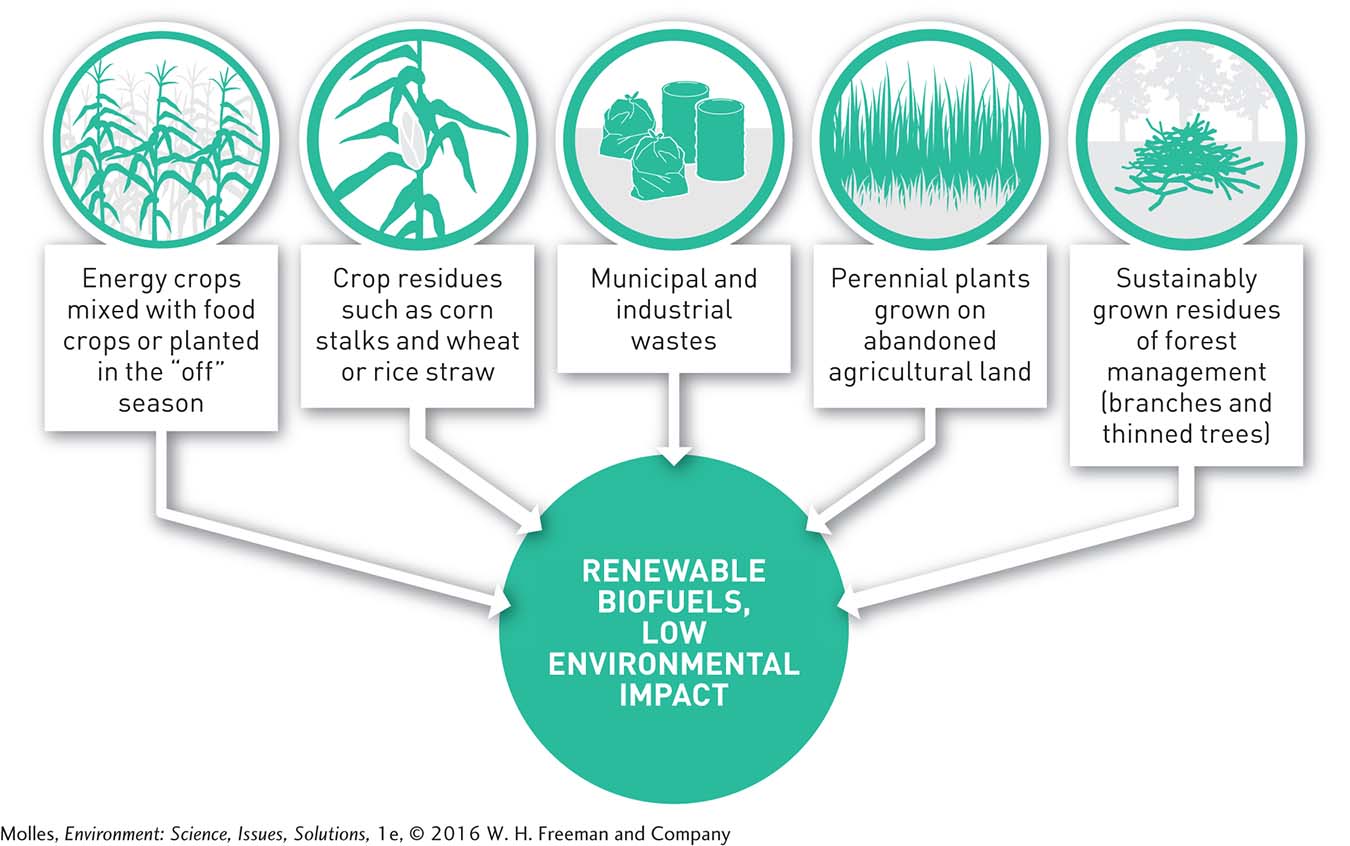

Recent reviews identify five promising sources of materials for cellulosic ethanol production (Figure 10.52). Developing these resources could improve environmental conditions in several ways. For example, growing perennial plants such as switchgrass (Panicum virgatum), native to most of the United States and Canada and that grows to 1 to 1.5 meters (3 to 5 feet) in height, has the potential to improve soil fertility by adding to soil carbon. In addition, switchgrass can grow well on a variety of soil types, including shallow soils of marginal fertility and low water content.

How might increasing demand for food from a growing human population influence the relative cost of cellulosic ethanol?

Think About It

Why is coupling legal protection with strong law enforcement essential to Brazil’s efforts to curtail deforestation?

How could development of systems for producing biofuels from aquatic algae complement land-

based biofuel production? How do improvements in fuel economy complement the development of new technologies for production of biofuels?

10.8–10.11 Solutions: Summary

A number of strategies and technological developments help address the environmental challenges facing solar energy development. Concentrating solar power plants using molten salt for heat transfer and storage use water-

New wind-

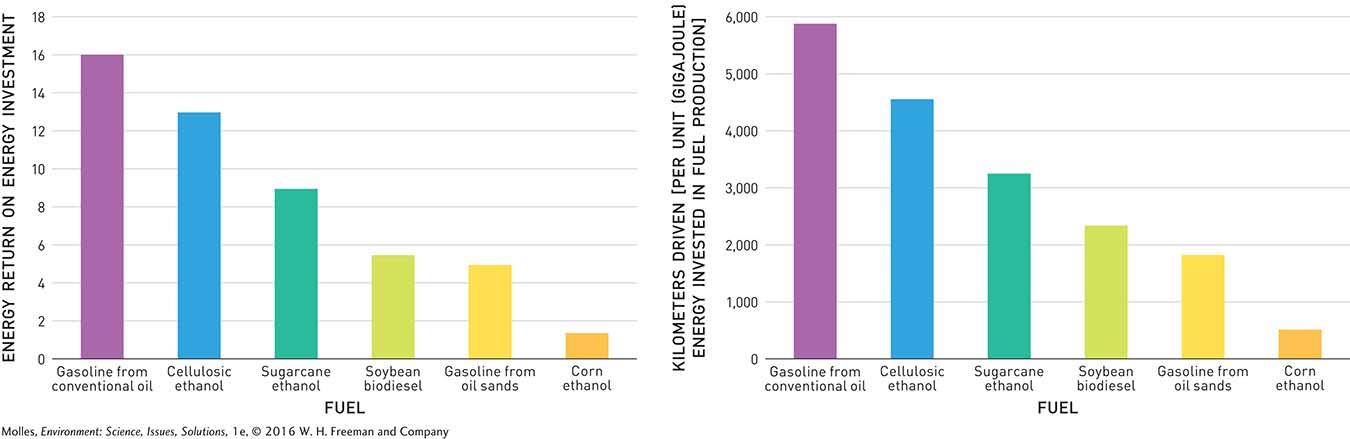

The dependence of the current transportation sector on petroleum-