ENGINEERING FOOD SAFETY: HACCP AND IRRADIATION

In 1963, as NASA geared up for its Gemini and Apollo missions, it realized that protecting astronauts from food poisoning was vital to successful space missions. On Earth a sick stomach might be unpleasant, but in space it could be catastrophic.

“You don’t want an astronaut with diarrhea,” said Robert Tauxe, a physician with the Centers for Disease Control and Prevention, in an interview with Frontline about the 1993 Jack in the Box outbreak.

HACCP (HAZARD ANALYSIS AND CRITICAL CONTROL POINTS) preventative food safety system that addresses the manufacture, storage, and distribution of food products

To help prevent what became known as the “two-

In essence, NASA scientists approached food safety as an engineering problem. Instead of focusing on end product inspection, they focused on the prevention of hazards. They analyzed and identified all of the possible points where germs (or other hazards) could enter the food supply, and then monitored these “critical control points” with a science-

IRRADIATION technology that uses low doses of radiation to destroy insects and bacteria in foods to improve food safety

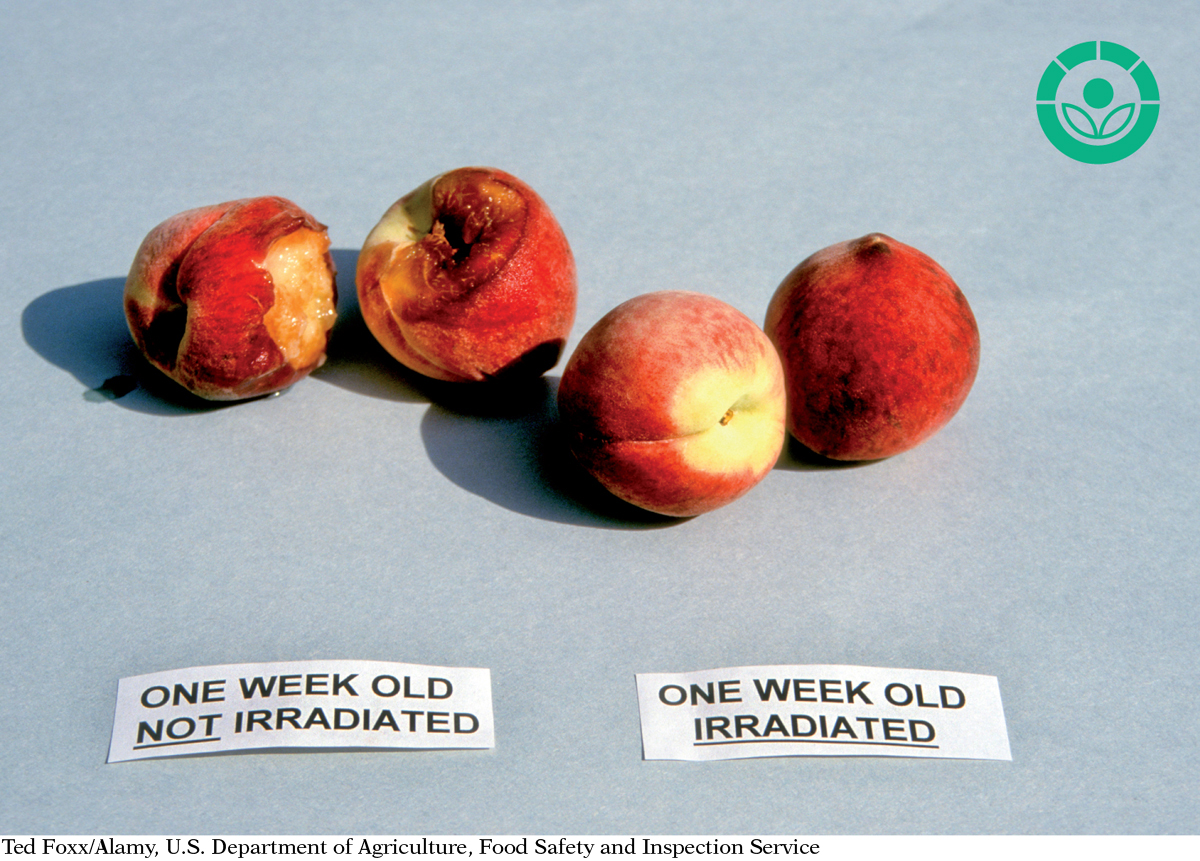

In addition to implementing HACCP, NASA also began, in 1972, to irradiate meat served to astronauts. Food irradiation kills bacteria, parasites, and insects by damaging DNA, which improves food safety. However, food irradiation does not kill all bacteria in foods so good food-

Although irradiated foods are generally not widely available, most spices sold wholesale in the United States have been irradiated. The effect of food irradiation has been studied extensively, and it has not been found to noticeably affect the taste or texture of foods, nor does it make foods radioactive or significantly reduce their nutrient content. You can determine if foods have been irradiated by looking for the international symbol for irradiation, as well as the statement “Treated with radiation” or “Treated by irradiation” on the food label. However, individual ingredients (such as spices) in multi-

What started out as a special program for astronauts soon spread to the wider civilian food supply. Beginning in the 1970s, HACCP was adopted by some companies voluntarily, since the companies had an interest in avoiding the bad publicity that can come from an outbreak. It was not until 1998, after the poisonings earlier in the decade, that HACCP became federally required for the meat industry. The system is now employed at the approximately 9,000 slaughterhouses in the United States.

Under the new HACCP system, instead of relying on USDA inspectors to test for contamination using the poke-

Because fruits and vegetables are not covered under USDA jurisdiction, spinach was not subject to HACCP. The FDA had been struggling for years to get the authority to enforce stronger protections on fruits and vegetables. But it was not until a major health crisis occurred, in the form of the spinach E. coli epidemic, that the political will was there.

“The thing that those 2006 outbreaks did was put the issue of on-