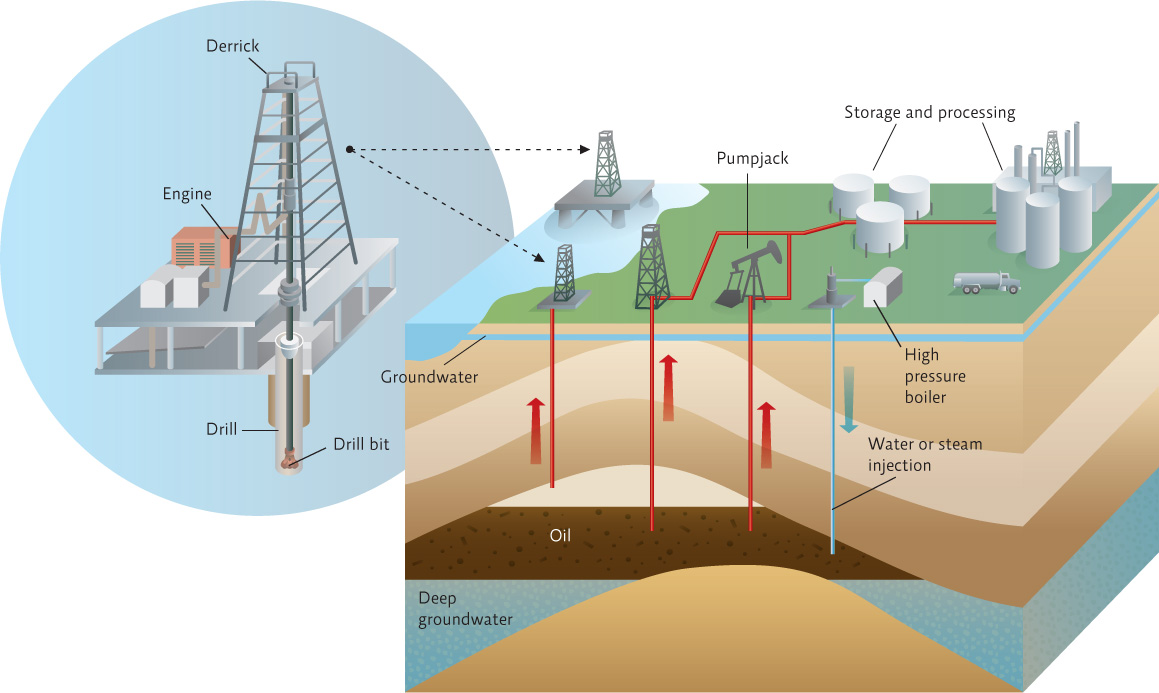

Conventional oil and natural gas reserves are tapped by drilling wells.

Initially, after a new oil well is drilled, nature does most of the work. There is significant pressure on oil located deep underground from millions of tons of rocks pressing down and from Earth’s heat, which causes gases around the oil and rock to expand. So when a well is first drilled, oil naturally flows upward, escaping like air gushing out of a balloon. This is known as primary production, and about 5% to 15% of the oil can be recovered in this first phase.

Eventually, the pressure on the trapped oil will decrease, so injection wells are drilled near the oil well, and huge hoses pump water through the injection wells into the ground. This increases the pressure on the remaining oil and forces more oil to the surface. During this phase of secondary production, an additional 20% and 40% of a reserve’s oil can be recovered.

KEY CONCEPT 19.3

Oil and natural gas often occur together in rock formations and are extracted from conventional reserves using oil and gas wells.

But even after maximal primary and secondary production (up to 55% of the total oil in the reserve), there is a lot of oil left in the ground. Tertiary production methods like injecting steam or carbon dioxide into the reservoir allow the additional recovery of up to 15% of the reserve’s oil, for a total production of up to 70% of the oil found in the reserve. INFOGRAPHIC 19.4

Oil is obtained by drilling through layers of dense rock to reach the reservoir below. At first, oil may easily flow due to the relief of pressure caused by the drill hole. Pumpjacks are used to mechanically pump out more oil when the oil stops flowing freely. Natural gas is also harvested from conventional deposits in this way.

Why aren’t pumpjacks needed during the initial retrieval of oil from a newly drilled well?

The oil in the deposit is exposed to high heat at this depth of the Earth which would cause the gases that surround the oil to expand, but the overlying cap rock prevents the gases from actually expanding. This puts the gases and oil under tremendous pressure. Piercing this by drilling a well releases some of that pressure, allowing the oil to flow freely up the well pipe without the need for a pump. After this initial release, more oil can be mechanically pumped out with a pumpjack.

With each more intensive production method, the energy return on energy invested (EROEI) goes down, and the cost goes up. A comparison of the EROEI for the extraction of different energy sources gives producers and investors useful information that helps determine which energy sources are worth pursuing. An energy source that requires almost as much energy to tap into as it ultimately produces will be left uptapped in favor of sources with higher EROEI values. (See Chapter 18 for more on EROEI.)

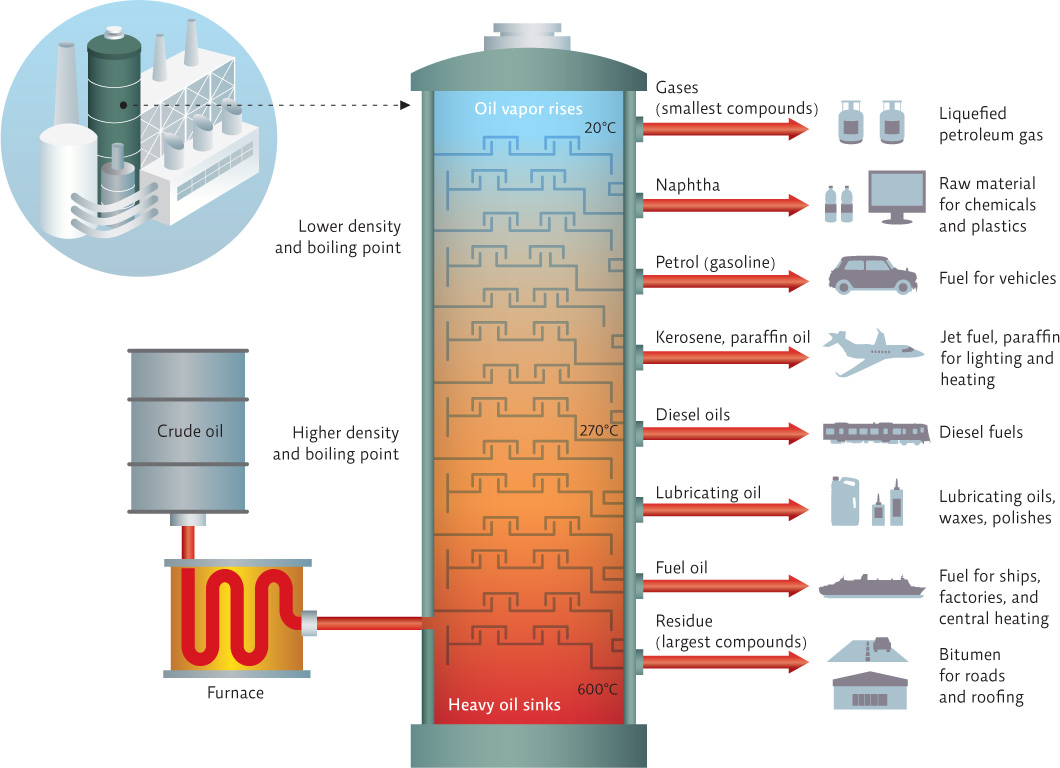

Because it contains so many impurities once it’s extracted from the ground, crude oil must be refined into a usable form. The refining process, called simple distillation, separates the oil into fractions, each with different hydrocarbon components. To do this, the crude oil is heated and put into a column or tower. As the oils boil off and rise in the column, the larger compounds condense back to liquid form and are collected. The first compounds to boil off include lighter liquids, like liquid petroleum gases and gasoline. Next come jet fuel, kerosene, and diesel fuel. Finally, at temperatures above 600°C (1,100°F), the heaviest products, including grease, wax, asphalt, and residual fuel oil, can be recovered.

KEY CONCEPT 19.4

Crude oil is refined by distillation to produce a variety of petrochemicals; about half of all oil goes to the chemical industry to produce plastics and other products.

Many of the products of distillation, called petrochemicals, are used not just as fuel but as raw materials in the production of industrial organic chemicals, pesticides, plastics, soaps, synthetic fibers, explosives, paints, and medicines. The production of a desktop computer, for example, consumes 10 times the computer’s weight in fossil fuels, mostly oil. INFOGRAPHIC 19.5

petrochemicals

Distillation products from the processing of crude oil such as fuels or industrial raw materials.

Crude oil is refined into a variety of chemical products by heating it in a tower. Different-sized carbon compounds “boil off” (vaporize) at different temperatures and heights within the tower and are collected as separate products.

Which of these is the longer hydrocarbon (longest molecule): naphtha or lubricating oil? How do you know?

Lubricating oils are longer; they require higher temperatures to boil off.

The importance of these fuels and petrochemical products to modern society cannot be overstated; they permeate our everyday lives and improve our quality of life. A shortage like the one that occurred during the oil crisis of the 1970s can send a nation into a panic and change global politics. It is no wonder we are constantly in search of new supplies, but as they become scarcer, the extent to which we will go to extract them has some people worried.