Extracting and processing mineral resources impacts the environment.

Deep in the Mojave Desert, hidden behind a colossal industrial gate about an hour’s drive from the glitz and glitter of Las Vegas, lies Mountain Pass, arguably one of the most important—and controversial—mines in the United States. It was the rare earth minerals harvested from this site—one mineral in particular, called europium—that in the 1960s turned black-and-white television into a Technicolor marvel and, in so doing, touched off a technology revolution that has stretched into the present day. Before the Mountain Pass reserves were discovered, human societies had little use for most rare earth minerals. But once europium’s usefulness became apparent, and miners started mining for it, they found a treasure trove of other rare earth minerals with properties that made them uniquely suited to a range of tasks.

“The real question is not ‘do we have enough’ . . . but rather ‘how far are we willing to go to access what we know is there?’”

—George Rossman

Gadolinium is used in medical MRI scanners; in fact, it is the very thing that makes MRIs possible. Lanthanum is used in military night-vision goggles and in automobile catalytic converters. And, more recently, neodymium has become the key ingredient in wind turbines and hybrid car batteries. The extreme magnetic ability of this and other rare earth minerals enables them to produce electric currents with very little material. And this, in turn, allows electronic devices to be miniaturized. It’s why we can use earbuds—instead of bulky headphones—to listen to our iPods.

To be sure, rare earth minerals are distinct from other minerals in several ways: They are tightly bound to one another, tend to be attached to lots of radioactive substrate, and are scattered diffusely through the ores that contain them—and all these factors present a string of unique mining challenges. Still, the story of Mountain Pass is like the story of most other industrial-scale mines.

It begins with geologists exploring various rock formations to pinpoint mining-worthy deposits—a science in itself, and one that requires remote sensing, exploratory digging or drilling, and chemical testing to evaluate samples. Once a deposit is located, minerals are extracted using one of several mining techniques. For large mining operations like Mountain Pass, virtually all of those techniques require large machinery and explosives to excavate tunnels, expose deposits, and dig out and transport ore. INFOGRAPHIC 26.4

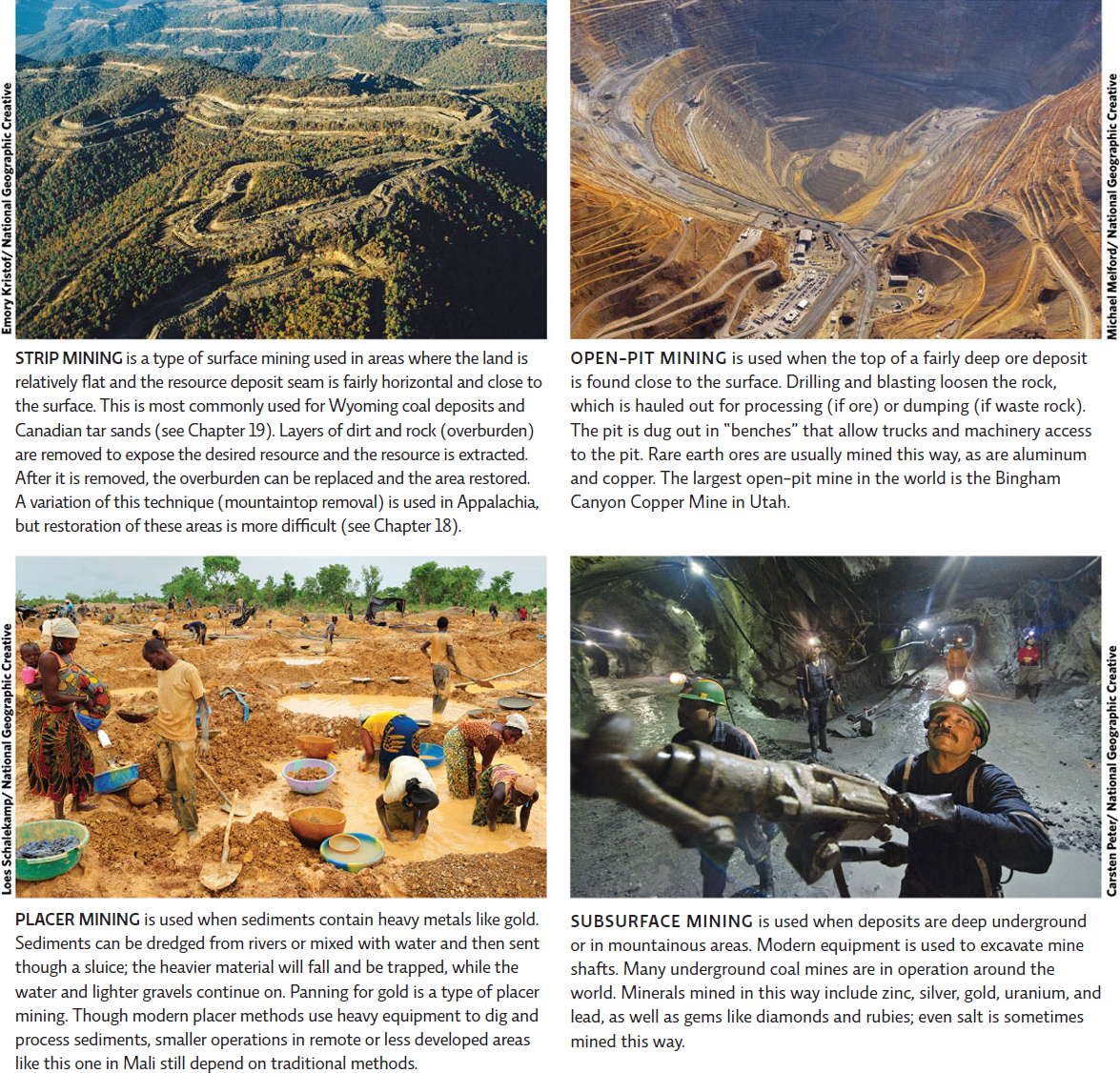

A variety of mining techniques are available to access mineral resources. The nature of the deposit (depth, concentration, type of ore) all influence the type of mining that will be done. Modern mining depends on heavy equipment and can move tremendous amounts of material in search of the desired mineral.

Why are a variety of mining techniques used to access mineral deposits?

Mineral deposits are found in different conditions and at different depths. Strip mining is used when deposits are shallow and close to the surface whereas open-pit mining will be used if a deposit is found close to the surface but goes quite deep. For deposits found deep underground but not close to the surface, sub-surface mines are used. For minerals found in sediments, placer mining (panning) is used.

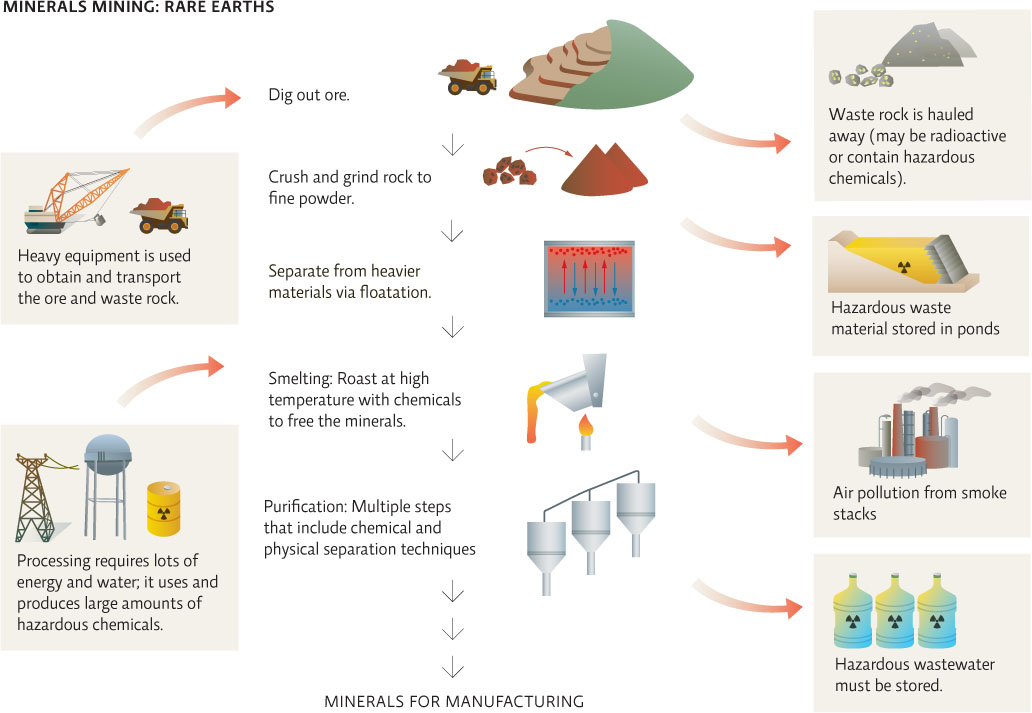

After it’s been dug out of the earth, the ore is sent through a series of machines known as crushers that grind the rock down into gravel and then grind it further still—into a fine powder. That fine-crushed powder is then heated to temperatures that, depending on the mineral being extracted, can exceed 1,000°C (1,800°F). During this step, the powder may be mixed with a suite of toxic chemicals—cyanide, mercury, various acids and bases—that bind to the metal, separate it from its non-mineral substrate, and pull it out of the treated sample. This process is known as smelting. Additional processing steps follow to purify the mineral in question, producing a form that can be used by manufacturers. INFOGRAPHIC 26.5

Like most other forms of ore mining, rare earth mining and processing is energy and water intensive and produces significant waste. Though the exact method differs at every mine, in general the process is the same. Tons of rock must be mined to produce small amounts of useful mineral, generating huge amounts of rock waste. The processing procedure requires multiple steps and produces significant amounts of hazardous waste (toxic and radioactive).

Which waste product from the mining and processing of mineral ores do you think is the most problematic in terms of being an environmental hazard that is difficult to deal with?

Answers can vary: Radioactive waste can be extremely hazardous to the health of organisms that encounter it, including workers, community members, and species that inhabit the area; air pollution can have effects far from the site of its production so might impact more parts of an ecosystem, more ecosystems in general, and thus more species and people; hazardous wastewater could also be extremely hazardous if it contains radioactive material and it has the potential to spread beyond the site of its storage if a spill occurs. Waste rock may be the least hazardous but can still damage ecosystems where it is dumped. What this tells us is that all waste from mineral mining and processing presents hazards that should be addressed.

The same story—search, discover, dig, extract, process—plays out at smaller-scale, “artisanal” mines around the world, where impoverished individuals use crude tools and simpler strategies to achieve the same ends. But as demand for mineral resources has grown, and prices have increased in tandem, large-scale operations like the one at Mountain Pass have come to dominate the landscape.

KEY CONCEPT 26.4

There are various high-tech and low-tech ways to mine mineral deposits, depending on the location, depth, and type of deposit.

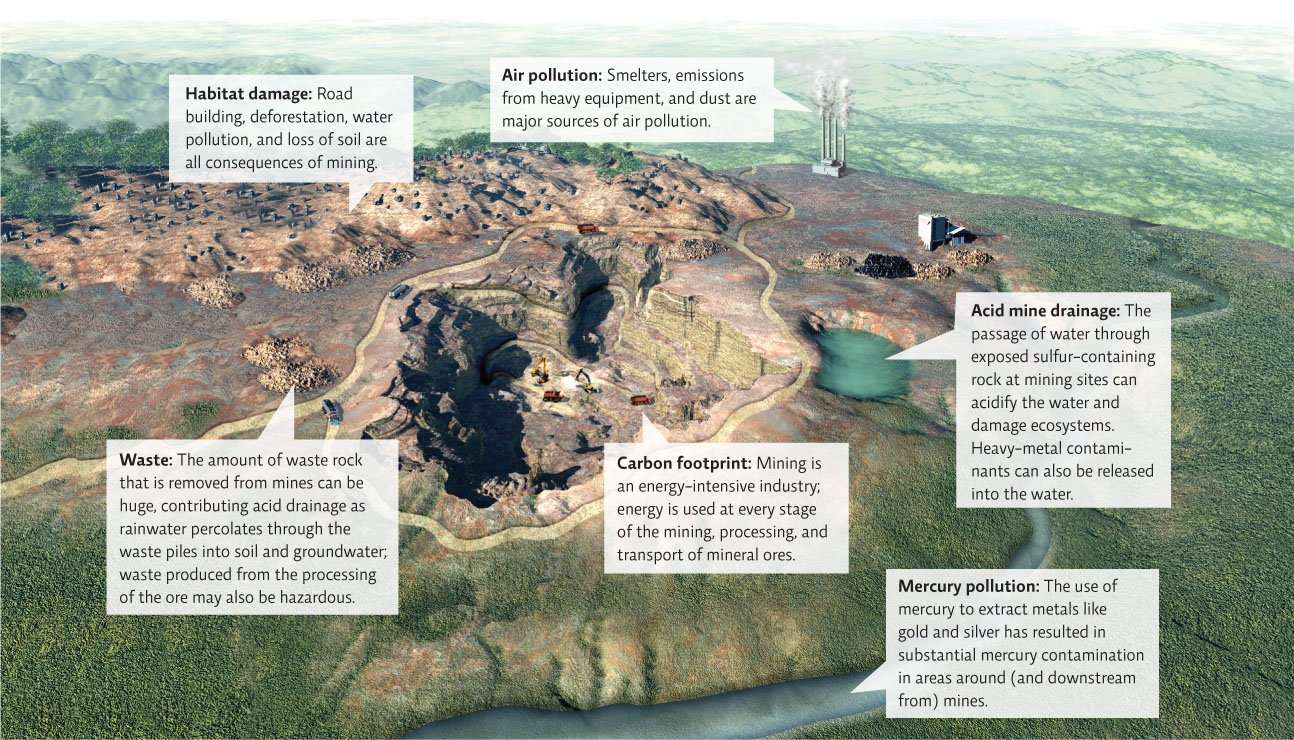

Such mechanization has increased mine productivity by an order of magnitude—mostly by enabling us to access previously unreachable deposits. But it has also increased the amount of waste produced by an order of magnitude—and in so doing has amplified the environmental and health consequences that mineral mining and processing bring with them. Large industrial mines often require that vast swaths of land be stripped bare and that an extensive web of roads be built for access and transport. These combined forces—deforestation and road building—contribute to both soil erosion and water pollution, as disturbed topsoil bleeds into nearby streams.

Indeed, it is nearly impossible to dig so much, and so deeply, into Earth without affecting the environment. Water traveling through underground mines or piles of waste rock and mill tailings (crushed ore that has been removed of its minerals and discarded) can collect all sorts of contaminants—not only heavy metals like mercury and arsenic that are detrimental to human health but also exposed sulfur, which lowers the water’s pH and produces acid mine drainage that in turn pollutes surface water and groundwater and harms aquatic ecosystems. Meanwhile, blasting, digging, crushing, and grinding all create dust, which pollutes the air with small particles and toxins and in some cases contains radioactive material.

KEY CONCEPT 26.5

The processing of mineral ores can require high water and energy inputs and can generate significant amounts of hazardous waste.

Large mining operations have developed a range of strategies to reduce this dust; they use huge amounts of water when crushing and grinding ore, and they store lightweight waste in ponds to keep it from floating through the air. But these solutions bring their own set of environmental problems—namely, they generate thousands of gallons of toxic, hazardous waste for every metric ton of minerals mined. And because that waste is so concentrated, the threat posed by a spill or leak is tremendous, especially for rare earth mines, where much of the waste is radioactive. INFOGRAPHIC 26.6

Because it digs up and moves so much earth, there are unavoidable environmental effects of mining.

What can be done to decrease the environmental impacts of mining?

Improving the energy efficiency of operations would decrease its carbon footprint. Habitat destruction might be lessened with more care given to the placement of waste rock and roads to avoid sensitive habitats; avoiding mining in sensitive areas would also be prudent. Water and air pollution controls should also be used as technology allows to decrease pollution from equipment, smelters and acid mine drainage. Restoration of mined areas after the mine is closed could also help mitigate some of the damage.

KEY CONCEPT 26.6

The environmental impacts of mining can be serious and include the production of hazardous wastes, habitat destruction, and air, water, and soil pollution.

Trouble started at Mountain Pass when the long, winding pipes that snaked from the mining pits to waste ponds began springing leaks. First one; then another. Then another—roughly 60 in all, between 1984 and 1994. The vast majority of them went unreported by the company in charge. By the time federal regulators noticed, investigated, and filed a report, some 2,300,000 liters (600,000 gallons) of radioactive, acidic, and otherwise hazardous waste had made its way into nearby lakes and the surrounding desert floor. Faced with $100 million in cleanup costs, a lawsuit from the district attorney’s office, and rapidly growing competition from China (where, thanks to lower wages and less regulation, newly discovered rare earth reserves were being mined much more cheaply than in the United States), the mine would be forced to close.

“The Mountain Pass debacle is kind of legendary,” says Brendan Cummings, an environmental attorney with the Center for Biological Diversity. “The environmental record there was just abysmal.” But in some ways, it was just a blip. In other parts of the world, regulation is frequently nonexistent, and accidents and violations tend to be much, much worse.