14.6 Indoor fish farming may provide a solution.

Zohar’s laboratory starts with water from the same supply that feeds household taps. By adding a precise mix of salts and trace elements, the lab creates its own seawater. The water is monitored and regulated by computer as the seawater cycles through the swimming pool-sized fish tanks and the network of pipes and filters that make up these miniature, indoor oceans. Everything about the artificial salt water—from its temperature, salinity, and pH, to its CO2 and oxygen concentrations—can be adjusted, on a tank-by-tank basis, to suit the species of fish and to mimic the changing conditions the fish would experience as they moved through both time and distance in the wild. “The entire system is biosecure,” boasts Zohar. “We don’t take a drop of water out of the harbour and we don’t drain a drop of water into the harbour.” In fact, the same thousands of litres of water are recycled over and over. Of course, in areas with water shortages, commandeering this much water to set up tanks may not be an option, so this may limit the applicability of this technology.

255

For Zohar, recirculating aquaculture represents a lifetime of research—each detail a carefully crafted response to the problems associated with existing aquaculture technology. Fish growing in Zohar’s tanks require less food per kilogram than the same fish grown in a net pen. The reason for this is simple: because there are waves and because salinity can’t be optimized, typical net pen fish expend more energy on movement and regulating their internal salt concentrations (osmoregulation) than they otherwise might. On top of that, food in the pens is not completely consumed; a portion of it sinks to the bottom of the pen, where it can’t be recovered or reused. In Zohar’s RAS setting, by contrast, aquaculturists can control food intake much better, and because salinity is always optimal, fish don’t have to invest as much energy in osmoregulation. As a result, they convert their food into flesh at a much higher ratio.

To further reduce the dependence on smaller marine fish as a food source, the researchers are experimenting with a variety of alternative feeds. The main contender so far seems to be algae. In a room adjacent to the fish tanks, long plastic tubes—the size, shape, and colour of colossal lime green freezies—hang from thin metal racks. Each one is filled with algae that will eventually be converted into food pellets (along with several other ingredients) and given to the fish. “All of the optimal ingredients in marine fish—the omega-3s, etc.—all come from the base of the food chain,” says Zohar. “So why not feed them algae?”

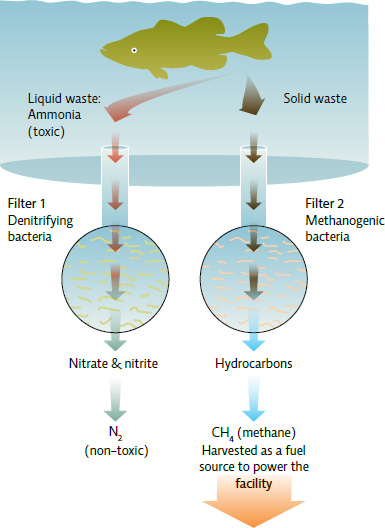

To manage accumulated liquid and solid waste, Zohar’s team employs carefully calibrated microbial communities that function much like they do in the ocean. One community converts ammonia into non-toxic forms; other bacteria convert 96% of the solid waste into fuel-grade methane. “So on top of all the other benefits, the system produces energy, about 10 litres of biogas every day,” Zohar explained, on a recent tour of the facility. That’s not enough to power the entire system, he says, but it certainly offsets some of the energy costs. [infographic 14.7]

As good as it all sounds, RAS facilities will have to meet a number of challenges before they can possibly hope to replace net pens. Net pens, for one, are much cheaper to set up and operate. The technology is simpler—and proven to work—and for fishers used to dealing with water and boats and navigation, growing fish in coastal or offshore net pens is less of a leap than growing them in warehouses.

“Systems like the one Yonathan has developed are definitely more environmentally friendly,” says Lorenzo Juarez, deputy manager of the U.S. National Oceanic and Atmospheric Administration (NOAA) Aquaculture Program. “But in our world, everything comes down to economics. If it’s going to take off, they have to prove it’s profitable.”

In a warehouse on the edge of Baltimore, tucked away from the harbour, Zohar and some business partners are trying to do just that. They’ve rented a nearly 17 000 square-metre space (that’s 7 times larger than the main lab) where they plan to scale up operations—from tanks the size of small, above ground pools, to tanks the size of large, in-ground pools, and from 2 metric tons of fish per year to 400 metric tons of fish per year. “That’s almost a million fish a year,” says Zohar’s business partner, David Wolf.

256

While the start-up costs are much higher than they would be for a net pen facility, RAS comes with its own set of advantages, too. For example, as Zohar and Wolf are quick to point out, the type of fish grown can be chosen based on economic opportunity rather than location. “So you can grow Mediterranean fish in Maryland or Minnesota,” says Wolf. “We could literally raise these fish next to a distribution house in Kansas, and because of that proximity, our fish will be fresher, and probably cheaper, too.”

Right now, roughly 85% of fish consumed in the United States is imported, often from great distances. Not only does that make the fish less fresh and more expensive, it also means the environmental footprint for Mediterranean fish consumed in U.S. restaurants—which includes fossil fuel for transportation and freezing, along with the resultant air pollution—is significant. By reducing the distance between the fishery and the consumer, RAS technology could make that footprint much smaller.

In an ideal world, aquaculture would provide the vast majority of fish we humans eat, while wild populations—along with the ecosystems they inhabit—would be left to recover, with only sustainable harvesting of healthy stocks. If RAS facilities prove commercially viable, coastal aquaculture ponds and net pen farms in developing countries could be scaled back, the mangrove swamps and coastal ecosystems they displaced could be restored, and, just maybe, fish could be produced, both profitably and sustainably, for local markets rather than shipped thousands of kilometres across the globe.

However, the start-up costs of a RAS facility make it unlikely to be feasible in poorer regions. Nor will large-scale RAS facilities be a viable option in water-starved regions, where such large quantities of fresh water can be difficult to come by. Meanwhile, the loss of net pen farms, while good for the environment, translates into a loss of income for areas that rely heavily on fish exports. As with many environmental problems, we must consider the triple bottom line (see Chapter 1) and take steps to address the social and economic issues as well as the environmental ones.

257

And finally, even if RAS operations can be made cost-effective, and the fish feed problem can be solved, and the fishers retrained, there will still be one more hurdle to clear before fish become as domesticated as chicken. Consumers must accept farmed fish, must come to think of them as no different than, or even better than, those harvested from the ocean. This may be an easier sell in developing countries, where some 2 billion people rely on fish protein for their very survival. But in North America, where fish protein is still something of a luxury, and where the first RAS facilities are just coming to life, Zohar knows that it will all come down to taste. That’s why, when the first harvest of Mediterranean sea bass was ready, he organized a cook-off at a local restaurant. Chefs from five nearby restaurants prepared two plates of five different dishes—one using wild caught fish and one using the fish he had grown in his laboratory fish farm. The result? “You couldn’t tell them apart,” says chef Damon Hersh, who participated in the contest. “They tasted exactly the same.”

Select references in this chapter:

FAO Fisheries and Aquaculture Department. 2010. The State of World Fisheries and Aquaculture. Rome: Food and Agriculture Organization of the United Nations.

Fisheries and Oceans Canada. 2013. Marine Protected Areas. www.dfo-mpo.gc.ca/oceans/marineareas-zonesmarines/mpa-zpm/index-eng.htm.

Krkosek, M., et al. 2007. Science, 318 (5857): 1772-1775.

Mason, F. 2002. The Newfoundland Cod Stock Collapse: A Review and Analysis of Social Factors. Electronic Green Journal, 1(17). http://escholarship.org/uc/item/19p7z78s#page-1.

Sea Around Us Project. 2011. EEZ Waters of Canada. http://www.seaaroundus.org/eez/124.aspx.

BRING IT HOME: PERSONAL CHOICES THAT HELP

While many see oceans as a vast and infinite resource, you now understand some of the threats facing our oceans and fisheries. By properly managing our fisheries, using sustainable harvest methods, and working to prevent and reduce the pollutants that enter our bodies of water, we can have oceans and rivers that support both aquatic life and human life for years to come.

Individual Steps

Educate yourself on which fish we should be eating: you can now check to see which fish species and locations have stable population levels and are being caught using sustainable methods. For an example, see www.seachoice.org, where you can search for recommended seafood choices, download a printable guide, or download the SeaChoice app for your smart phone.

Educate yourself on which fish we should be eating: you can now check to see which fish species and locations have stable population levels and are being caught using sustainable methods. For an example, see www.seachoice.org, where you can search for recommended seafood choices, download a printable guide, or download the SeaChoice app for your smart phone.

When purchasing prepackaged or fresh fish in a grocery store or restaurant, look for the Marine Stewardship Council seal, which labels products sourced from wild-caught fisheries that have been independently certified to the MSC environmental standard.

When purchasing prepackaged or fresh fish in a grocery store or restaurant, look for the Marine Stewardship Council seal, which labels products sourced from wild-caught fisheries that have been independently certified to the MSC environmental standard.

Group Action

Organize a beach or river clean-up to prevent pollution from entering waterways.

Organize a beach or river clean-up to prevent pollution from entering waterways.

Policy Change

Write or talk to restaurant owners to ask them to serve only fish that are considered sustainable.

Write or talk to restaurant owners to ask them to serve only fish that are considered sustainable.

Write your policy makers to encourage them to establish marine protected areas and support legislation that protects aquatic health.

Write your policy makers to encourage them to establish marine protected areas and support legislation that protects aquatic health.

258