20.3 Conventional oil reserves are tapped by drilling wells.

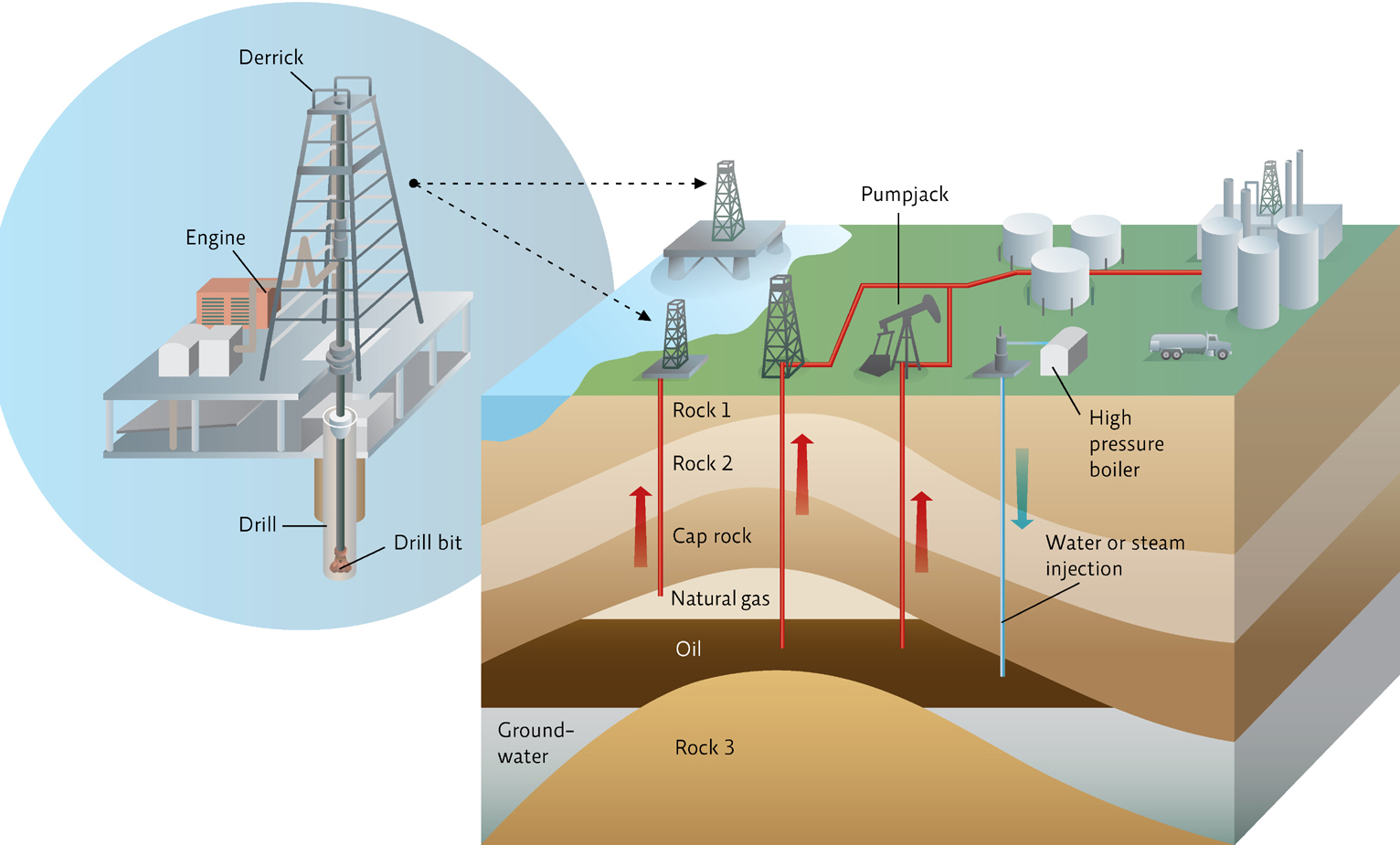

Most conventional crude oil is mined by simply drilling a new oil well, after which nature does much of the work. There is significant pressure on oil deep underground from millions of tons of rocks pressing down and from Earth’s heat, which causes gases around the oil and rock to expand. So when a well is first drilled, oil naturally flows upward, escaping like air gushing out of a balloon. This is known as primary production, and about 5 to 15% of the oil can be recovered in this first phase.

Eventually, the pressure on the trapped oil will decrease, so injection wells are drilled nearby and huge hoses pump water through the wells into the ground. This increases the pressure on the remaining oil and forces more oil to the surface. During this phase of secondary production, between 20 and 40% of a reserve’s oil can be recovered.

But even after primary and secondary production, there is a lot of oil left in the ground. Tertiary production methods such as injecting steam or CO2 into the reservoir allow the recovery of up to 60% of the remaining oil but are costly in both money and energy. [infographic 20.5]

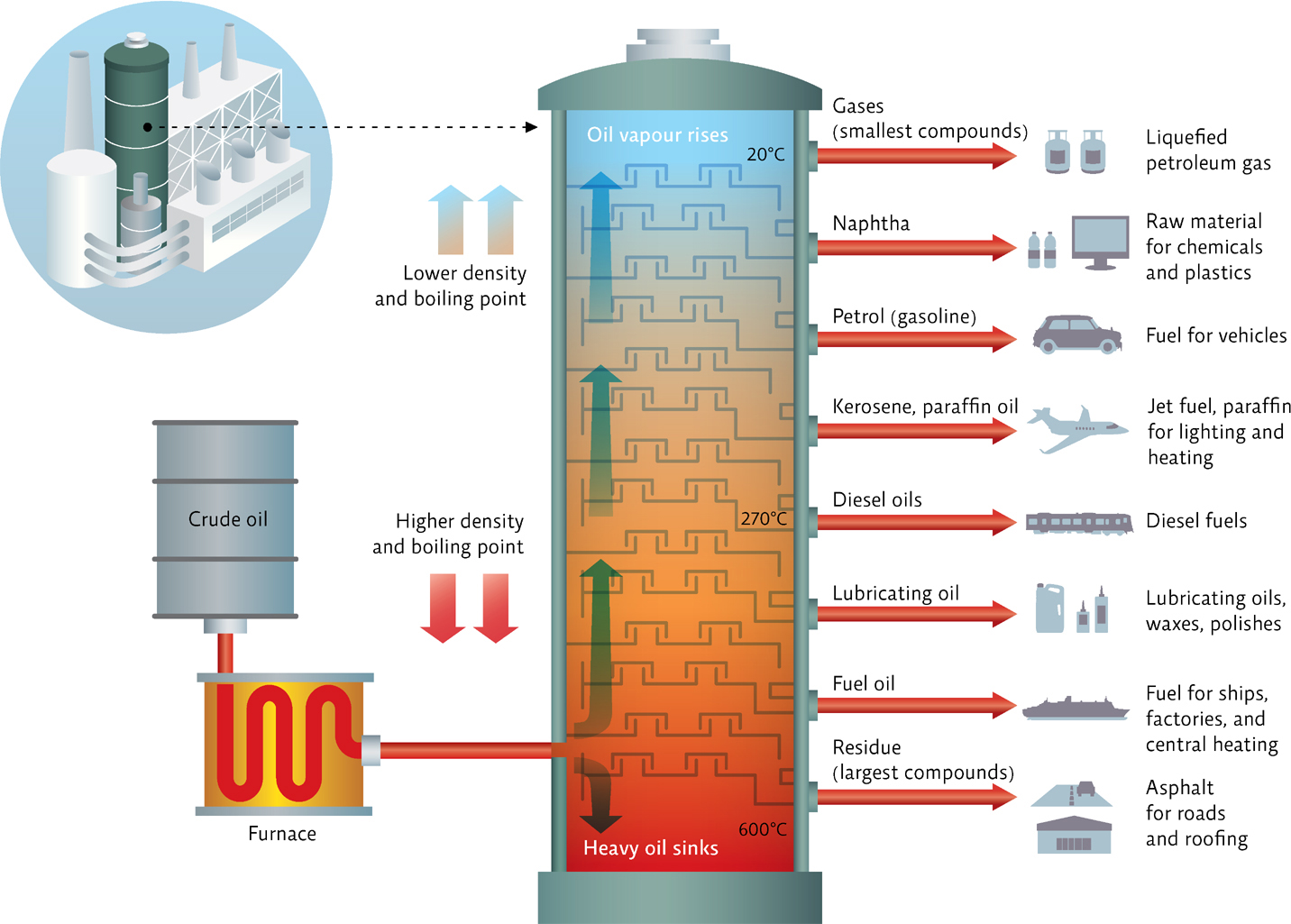

Because it contains so many impurities once it’s extracted from the earth, crude oil must be refined into a usable form. The first refining process, called simple distillation, separates the oil into fractions, each with different hydrocarbon components. To do this, the crude oil is heated and put into a column, or tower. As the oils boil off and rise in the column, the larger compounds condense back to liquid form and are collected. The first compounds to boil off include lighter liquids, like liquefied petroleum gases and gasoline. Next come jet fuel, kerosene, and diesel fuel. Finally, at temperatures above 600°C, the heaviest products, including grease, wax, asphalt, and residual fuel oil, can be recovered.

Many of the products of distillation, called petrochemicals, are used not just as fuel but as raw materials in the production of industrial organic chemicals, pesticides, plastics, soaps, synthetic fibres, explosives, paints, and medicines. The production of a desktop computer, for example, consumes 10 times the computer’s weight in fossil fuels, mostly oil. [infographic 20.6]

359