Life-cycle analysis and better design can help reduce waste.

The real trick to keeping garbage out of the ocean is to go back to the beginning, before the things we throw away are even made. Environmentally friendly products continue to grow in popularity, and manufacturers have given a name to the tactics used to create these products: life-cycle analysis. By assessing the environmental impact of every stage of a product’s life—from production, to use, to disposal—an increasing number of companies are trying to reduce the amount of waste generated by the things they design, make, and sell. Cradle-to-cradle analysis takes this even further as it tries to increase reuse potential and turn waste back into resource (see Chapter 6).

Part of this shift has been spurred by legislation. Some European countries and at least 19 U.S. states have implemented “take-back laws,” which require manufacturers to take back some of their products— namely, computers—after consumers are finished with them. This creates an incentive for manufacturers to design products from which components can easily be salvaged and reused. Indeed, many companies are trying to cut down on waste by de-manufacturing—or disassembling equipment, machinery, and appliances into the component parts so that those parts can be reused. BMW, for example, designs its vehicles so that at least 97% of the components can be reused or recycled.

KEY CONCEPT 7.7

We can reduce industrial waste by identifying ways to use resources more efficiently so there is less waste to begin with, and then identifying ways to reuse and recycle waste that is produced.

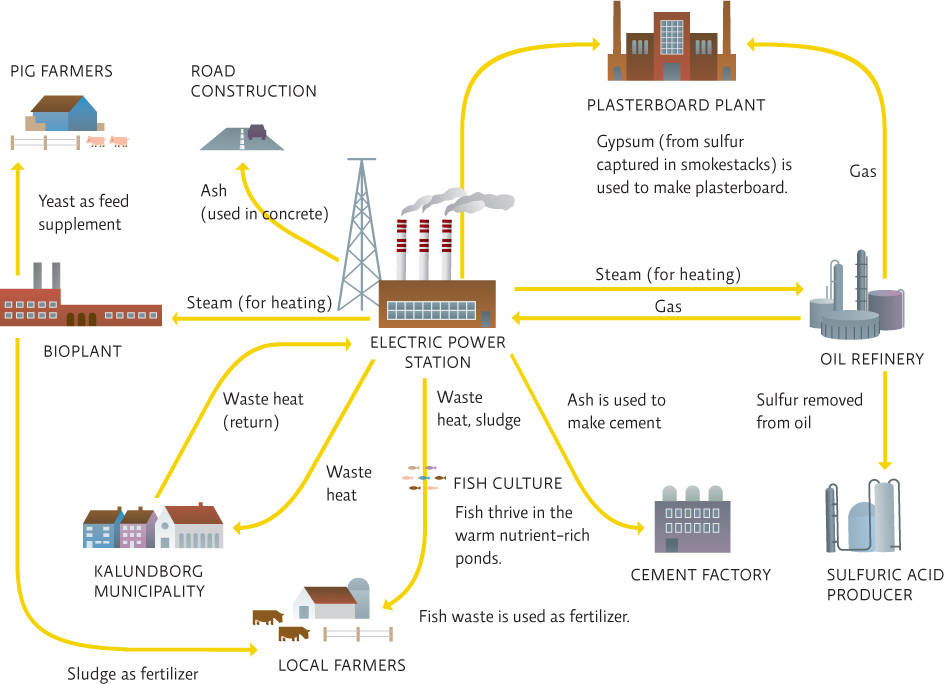

On a grander scale, in eco-industrial parks, industries are positioned so that they can use each other’s waste in the same industrial area; one company’s trash becomes another’s raw material. This type of strategic thinking is known as industrial ecology; in addition to “waste-to-feed” exchanges, participants in eco-industrial parks also decrease their ecological footprint by coordinating activities and sharing some spaces, like warehouses and shipping facilities. This form of waste reduction can occur within a single company, between two companies, or between a company and a community. For example, one UK company sells the soapy water produced by its shampoo manufacturing plants to area car washes rather than throw it away. The same company also uses its ethanol waste—a by-product of its manufacturing processes—to heat some of its facilities. INFOGRAPHIC 7.7

eco-industrial parks

Industrial parks in which industries are physically positioned near each other for “waste-to-feed” exchanges; the waste of one becomes the raw material for another.

The industrial park in Kalundborg, Denmark, is a prime example of industrial ecology. Here, by design, there are 24 different connections between various industries and local farms, such that the waste of one becomes the resource for another.

Suppose a community wanted to transition an industrial park to the eco-industrial model. Explain how a life-cycle analysis of the industry products already made there can help determine which other industries to “invite” to join their park.

A lifecycle analysis will reveal what raw materials the industries need to produce their products (to invite in those that might produce these materials as a waste product) and what waste products are being produced by the industries there (to identify what other industries might be able to use that waste as a raw material).